Ductile Iron Coated Sand Casting Shell Casting with Machining

Product Description

Product Description:

Casting (metalworking)

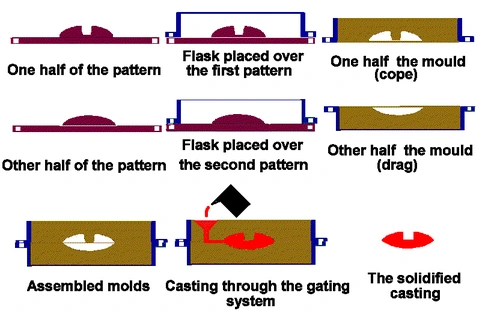

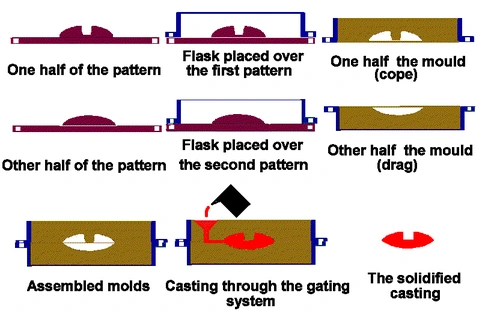

In metalworking, metal is heated until it becomes liquid and is then poured into a mold. The mold is a hollow cavity that includes the desired shape, but the mold also includes runners and risers that enable the metal to fill the mold. The mold and the metal are then cooled until the metal solidifies. The solidified part (the casting) is then recovered from the mold. Subsequent operations remove excess material caused by the casting process (such as the runners and risers).

Why choices us?

Our Products:

1. AUTO Parts, classic car parts

2. machine parts, pump body housing, engine parts, cylinders, pistons, transmission housing.

3. cookware parts, kitchen ware parts.

4. medical equipment parts, housing, instrument housing, I beam, housing...etc.

5. Bicycle and motocycle parts, sport equipment parts, housings, covers, heat sinks.

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

Transport:

Product Specifications: | |

| Material: | Stainless STEEL,Alloy Steel,Brass,COPPER,ALUMINUM,Aluminium alloy,Iron etc. |

| Dimension: | According to the drawing or sample |

| Standard: | DIN GB ISO JIS BA ANSI |

| Casting tolerance: | IT5 - IT7,CT5-7 |

| Production Process: | Polish/Sand Blast/EDM/Milling/Texture/Grind/Pre-Treatment/Quenching/Lathe/Wire Cut/Annealing/Temper etc. |

| Machining tolerance: | +/- 0.005mm,ISO2768-f,ISO-mk |

| Weight range: | 0.1Kg-120Kg |

| Dimensions: | ≤1200mm×800mm×400mm |

| Surface finishment: | Ra1.6-Ra3.2 |

Casting (metalworking)

In metalworking, metal is heated until it becomes liquid and is then poured into a mold. The mold is a hollow cavity that includes the desired shape, but the mold also includes runners and risers that enable the metal to fill the mold. The mold and the metal are then cooled until the metal solidifies. The solidified part (the casting) is then recovered from the mold. Subsequent operations remove excess material caused by the casting process (such as the runners and risers).

| Typical | Feasible | |

| Shapes: | Thin-walled: Complex Solid: Cylindrical Solid: Cubic Solid: Complex | Flat Thin-walled: Cylindrical Thin-walled: Cubic |

| Part size: | Weight: 1 oz - 450 ton | |

| Materials: | Metals Alloy Steel Carbon Steel Cast Iron Stainless Steel Aluminum Copper Magnesium Nickel | Lead Tin Titanium Zinc |

| Surface finish - Ra: | 300 - 600 μin | 125 - 2000 μin |

| Tolerance: | ± 0.03 in. | ± 0.015 in. |

| Max wall thickness: | 0.125 - 5 in. | 0.09 - 40 in. |

| Advantages: | Can produce very large parts Can form complex shapes Many material options Low tooling and equipment cost Scrap can be recycled Short lead time possible | |

| Disadvantages: | Poor material strength High porosity possible Poor surface finish and tolerance Seondary machining often required Low production rate High labor cost | |

| Applications: | Engine blocks and manifolds, machine bases, gears, pulleys | |

Why choices us?

- In China, we have more than 13 years of experience in processing foreign companies for foreign companies.

- China manufacturer in Qingdao,not trade company

- Competitive price and nice service

- ISO/SGS passed

- Application: Automotive,medical device, electronics, toy, furniture, industrial etc

Our Products:

1. AUTO Parts, classic car parts

2. machine parts, pump body housing, engine parts, cylinders, pistons, transmission housing.

3. cookware parts, kitchen ware parts.

4. medical equipment parts, housing, instrument housing, I beam, housing...etc.

5. Bicycle and motocycle parts, sport equipment parts, housings, covers, heat sinks.

Our Policy:

Innovation and developing in Technique

High level of expertise

Outstanding quality

On-time delivery to customer needs

Transport:

Product Categories : Casting Parts > SAND CASTING

Premium Related Products

Other Products

Hot Products

Water Lubricated Rubber Bearing Based on Cutless Bearing,Oilless Sliding Bushing with PTFE+Steel Backing,SF-1 Series DU BushingFAW King Pin Bush Precision POM Pin Bush PVB020X Bronze Pins and Bushings OEM ManufacturerJIS/DIN Standard Plate/Flat Flange Thrust Washer Oiles Sliding Thrust Washerball bearing guide bush,ball retainer ball cages,ball bearingsFlange DU Bearing Bush,Composite DU Bushing,Metric DU Sleeve Bushing BearingFlanged POM bearing,LFX Bushing,DX Flanged Bushing BearingSS304 Stainless steel bush, SS316 Stainless steel bearing bushing, SF-1S dry sliding bearingTorque Rod Bushing, bimetal bushes for AMW Truck, Bogie Bearing BushingSO#50 SP2 Bronze Plates,Oiles Slide Plates Manufacturer, FPLB20-305-05 Bronze Plates with GraphiteBronze Bearing Factory,Bronze Bushing supplier,CuSn8 flange bronze bushmanganese bronze bearing,SPB506060 Bearing Bushing,oiles sleeve bushing bearingBPW cooper Bushing,BPW axle bronze bearing,BPW Bush bearing supplierMBZ Bronze Bushing, Split bronze bearing,Bronze sleeve bearing supplierHigh quality bronze bearing pad,Graphite oiles slide plates,#500 oiless wear platesHigh Quality Cast Bronze bearing, Oil Grooves cast Bronze bushing bearing, Cast Brass bush ManufacturerOiles Bronze Bush,Cast Bronze Bearing Manufacturer,Oilless Bronze Bushing